Plastic T Sections

TP Extrusions stock and produce to order a wide range of Plastic T Sections in varied sizes and designs, for joint filling, use as bumper strip and general edge protection. T Barb profile is usually knocked into a groove and is popular in different flexible and rigid materials, and Plastic T profile with a straight stem can be used to cover Board and Panel joints. Please contact us to discuss T Section requirements if you cannot find what you want.

However if you cannot find what you are looking for we offer a Custom Plastic Extrusion Option and would welcome your enquiry.

The Plastic Tee Profiles on this page complement the other Board and Panel plastic profiles that we supply. Pages detailing our Plastic H Sections, Plastic Corner Joints, Plastic Capping and Plastic Clip-on Edging can be reached from our Board and Panel Landing Page.

Stock Plastic T Sections

Plastic Tee Section is stocked in flexible and rigid PVC, in a variety of colours. It is possible to use stock tooling for production runs.

For details of pack sizes and prices on stock rigid plastic Tee Section please visit our sister site Stock Plastic Profiles Large Board and Panel page. For details of our stock flexible plastic Tee Section please visit the Stock Plastic Profiles Flexible Edgings page.

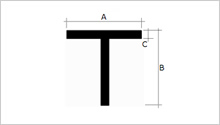

T Barbed

T Equal

| Dimensions in mm | ||||||

| Ref | DWG | A | B | C | D | Materials / Comments |

| TP08 2102 | T Barbed | 12.5 | 5.4 | 2.1 | – | STOCK flex pvc, colour choice |

| TP08 2101 | T Barbed | 16 | 6.5 | 3.3 | – | STOCK flex pvc, colour choice |

| TP08 2100 | T Barbed | 19 | 11 | 3.3 | – | STOCK flex pvc, colour choice |

| TP08 0066 | T Barbed | 19 | 11 | 3.4 | – | STOCK rigid pvc, colour choice |

| TP08 0161 | T Barbed | 25 | 11.5 | 3.4 | – | STOCK rigid pvc, colour choice |

| TP08 0098 | T Equal | 19 | 17.8 | 1.6 | – | STOCK rigid pvc, colour choice |

| TP08 0160 | T Equal | 25 | 14 | 1.6 | – | STOCK rigid pvc, colour choice |

| TP08 0186 | T Equal | 38 | 17 | 2 | – | STOCK rigid pvc, colour choice |

| TP08 0187 | T Equal | 50 | 10.3 | 1.7 | – | STOCK rigid pvc, colour choice |

For details of pack sizes and prices on stock rigid Tee Section please visit our sister site Stock Plastic Profiles Large Board and Panel page. For details of our stock flexible Tee Section please visit the Stock Plastic Profiles Flexible Edgings page.

Custom Plastic T Sections

The tooling detailed here is for made to order Plastic Tee Sections and bumper profiles. If the size or design you are looking for is not listed, tooling will generally be simple and cost effective to make, so please contact us to discuss any Plastic T Section tooling enquiries.

However if you cannot find what you are looking for we offer a Custom Plastic Extrusion Option and would welcome your enquiry.

Please note that where a tool is described as “Flexible”, the profile can only be run in this material. All other tooling is suitable for both rigid and flexible production.

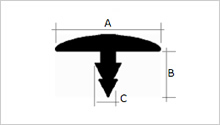

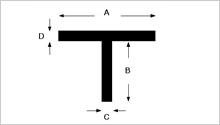

Generic T Section Dimensions

| Dimensions in mm | |||||

| Ref | A | B | C | D | Materials / Comments(** drawing below) |

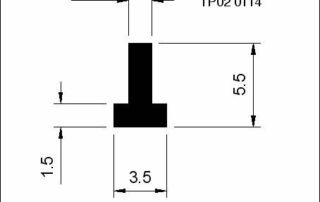

| TP02 0114 | 3.5 | 4 | 1.5 | 1.5 | Straight stem ** |

| TP01 0113 | 3.6 | 1.5 | 1.7 | 1.9 | Flat top, bumps on stem |

| TP08 W205 | 4.25 | 20 | 2.9 | – | Straight stem |

| TP05 0973 | 5 | 16 | 1 | 1 | Flexible, flat top, straight stem |

| TP08 W094 | 6.4 | 14.3 | 1.1 | 4.7 | Raised cap** |

| TP05 1123 | 8.9 | 4.6 | 3.8 | 2.3 | Domed top, straight bullnosed stem |

| TP08 W127 | 9 | 2 | 2.5 | – | Straight stem |

| TP05 1692B | 9 | 6.1 | 2.8 | 1.5 | Flat top, barbed stem |

| TP05 1792 | 9.5 | 5.6 | 3.2 | 4.5 | Domed raised top, barbed stem** |

| TP02 B002 | 10 | 3.5 | 1.5 | 1 | Domed top, barbed stem |

| TP02 0017 | 10 | 5 | 4.7 | 2 | Bumper profile, straight stem |

| TP06 0116 | 10 | 6 | 3.2 | 2 | Flexible PVC, barbed, metallic foil finish** |

| TP05 1692 | 10 | 6.1 | 3.4 | 1.5 | Flat top, barbed stem |

| TP08 W084 | 10.5 | 13 | 1 | 2.5 | Offset stem |

| TP05 1191 | 11.5 | 5.3 | 1.1 | 1.1 | Flat top, straight stem |

| TP05 1698 | 12 | 6.12 | 3.4 | 1.5 | Flat top, barbed stem |

| TP05 1675 | 12.5 | 6.1 | 3.5 | 1.5 | Flat top, barbed stem |

| TP02 B003 | 13 | 6.5 | 2.5 | 1.2 | Flat top, barbed stem |

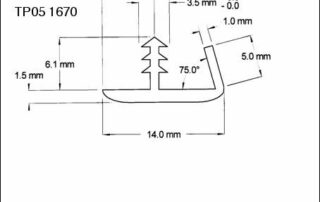

| TP05 1670 | 14 | 6.1 | 3.5 | 1.5 | Flexible, 5mm lip on one side, barbed stem** |

| TP02 B004 | 14.5 | 6 | 2.5 | 2 | Domed top, barbed stem |

| TP05 1056A | 15 | 5 | 2.5 | 1.7 | Flexible, domed top, barbed stem |

| TP01 2022 | 15 | 6 | 5.7 | – | Domed raised top, tapering stem |

| TP05 1284 | 15 | 7 | 3.2 | 3 | Flat top, barbed stem |

| TP05 1162A | 15 | 7 | 3.5 | 1.5 | Flexible, domed top, barbed stem |

| TP05 1791 | 15 | 8 | 3.5 | 21.5 | Domed raised top, barbed stem** |

| TP08 W026 | 16 | – | 3.7 | – | Barbed stem |

| TP02 B006 | 16 | 6.5 | 3 | 2.3 | Domed top, barbed stem |

| TP02 B005 | 16 | 7 | 3 | 1.5 | Flat ridged top, barbed stem |

| TP05 1056 | 18 | 6 | 3 | 2 | Flexible, domed top, barbed stem |

| TP02 2056 | 18 | 7 | 3.8 | 2.8 | Domed top, barbed stem |

| TP08 W130 | 18 | 19 | – | – | Barbed stem |

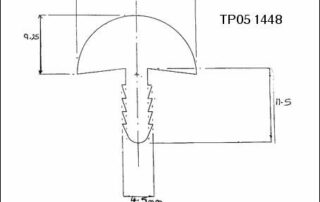

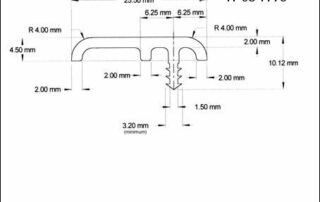

| TP05 1448 | 18.5 | 11.5 | 4.5 | 9.25 | Flexible, thick domed top, barbed stem** |

| TP05 1162 | 19 | 7 | 3.5 | 1.5 | Flexible, domed top, barbed stem |

| TP02 B007 | 19 | 7.5 | 3 | 3 | Domed top, barbed stem** |

| TP08 W069 | 19 | 8 | 3.8 | – | |

| TP08 W073 | 19 | 8.5 | 3.5 | – | Barbed stem |

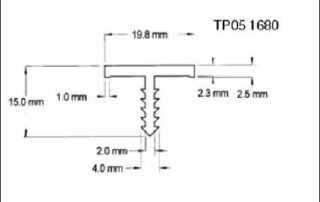

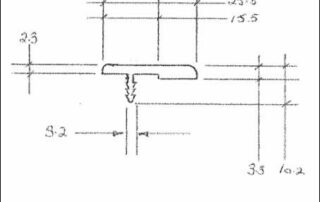

| TP05 1680 | 19.8 | 12.5 | 4 | 2.5 | Flat top, barbed stem** |

| TP01 0146 | 20 | 6 | 2 | 3 | Flexible, domed top, offset stem with hook |

| TP08 W122 | 20 | 8 | 3.5 | – | Barbed stem |

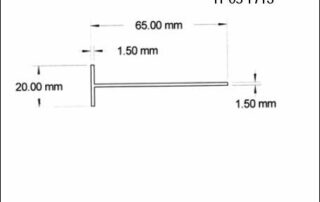

| TP05 1713 | 20 | 63.5 | 1.5 | 1.5 | Flat top, straight stem** |

| TP02 B008 | 21 | 7.5 | 3.5 | 2 | Flat top, barbed stem |

| TP05 1057 | 22 | – | – | – | Flexible, domed top, barbed stem |

| TP02 B009 | 22 | 9 | 4.5 | 3.5 | Domed top, barbed stem |

| TP02 B010 | 23 | 9 | 4.5 | 3.7 | Domed top, barbed stem |

| TP02 B013 | 24 | – | 3.5 | – | Cap hooks over 18.5mm board, barbed stem |

| TP05 1779 | 25.5 | 5.62 | 3.2 | 4.5 | Flat raised top, barbed off centre stem** |

| TP08 W024 | 25.8 | 7.9 | 3.2 | 2.3 | Offset barbed stem wth overhang one side** |

| TP05 1453 | 26 | 7 | 3.3 | 2.75 | Flat lipped top, barbed off centre stem |

| TP05 1452 | 26 | 10 | 3.3 | 3 | Flat top, barbed stem |

| TP05 1639 | 27.5 | 12 | 4.2 | 3 | Flat top, barbed stem |

| TP02 2188 | 28 | 8.9 | 2.8 | 2.8 | Domed top, barbed stem |

| TP05 1793 | 29.2 | 15.2 | 2.5 | 2.5 | Flat top, straight off centre stem |

| TP02 B011 | 30 | 9.5 | 3 | 3 | Domed top, barbed stem |

| TP02 B012 | 33 | 10 | 3.2 | 3.5 | Domed top, barbed stem |

| TP08 W321 | 35 | 33.5 | 1.5 | – | Barbed stem |

| TP08 W067 | 38 | 17 | 6.2 | – | Barbed stem |

| TP02 B001 | 40 | 14 | 2 | 2 | Flat top, straight stem |

| TP08 2154 | 45 | 10 | 1.3 | – | Offset straight stem |

| TP08 2031 | 50 | 12.7 | 1.4 | – | Barbed stem |

Click on a thumbnail image for a larger version of these custom plastic extrusions: