Special Plastic Tubes

TP Extrusions has plastic extrusion tooling available for a variety of unusual and non-standard plastic tubes which have been designed for particular applications. Please see the details and drawings below for specifics. If the profile shape, dimensions or features you are interested in are not included, we will be able to make custom plastic extrusion tooling for you – contact us to discuss or click here for Plastic Tube tooling details.

Note that apart from some of the oval plastic tubes, these extruded plastic profiles are not stocked but are run to order and subject to minimum order quantities. This enables us to cut to lengths, to your instructions, of up to 5m.

If you require round, square, rectangular or flexible tubing, click through.

Oval Plastic Tubes

Oval tubes have several standard uses, such as Electrical Conduit and athletics Hurdle Rail bars. It is possible in some cases to run with different wall thicknesses, as well as a choice of colour and plastic material.

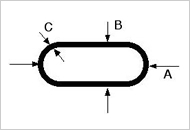

| Dimensions in mm | ||||

| Ref | A | B | C | Materials/Comments |

| TP08 0079 | 14.3 | 10 | 1.2 | STOCK rigid pvc |

| TP08 0080 | 22 | 12 | 1.2 | STOCK rigid pvc |

| TP08 0081 | 28 | 11 | 0.8 | STOCK rigid pvc |

| Dimensions in mm | ||||

| Ref | A | B | C | Materials/Comments |

| TP05 T254 | 13 | 8 | 1-1.5 | UPVC, ABS, HIPS |

| TP05 T255 | 17 | 10 | 1-1.5 | UPVC, ABS, HIPS |

| TP05 T256 | 22 | 12 | 1-1.5 | UPVC, ABS, HIPS |

| TP05 T257 | 29 | 12 | 1-1.5 | UPVC, ABS, HIPS |

| TP02 T260 | 54 | 9.5 | 1.75 | UPVC, ABS, PP, Polythene |

| TP05 1890 | 60 | 20 | 1.5 | UPVC, ABS, HIPS – 4 internal lugs |

| TP07 0124 | 70 | 20 | 3 | UPVC, ABS, HDPE, PP, PC, Styrene |

Click on a thumbnail image for a larger version:

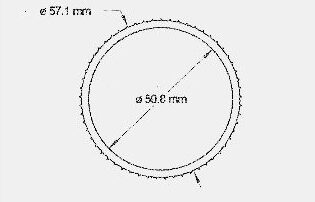

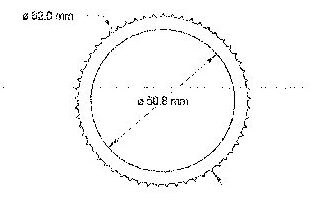

Ribbed Plastic Tubes

These tubes are also known as fluted tubes, towel or grab rails, and can be used in conveyor belt type applications. It is possible for some ribbed tubing to be run in different wall thicknesses to suit your requirements.

| Dimensions in mm | ||||

| Ref | A | B | C | Materials/Comments |

| TP02 T250 | 14.2 | – | 1+ | UPVC, ABS, PP, Polythene |

| TP02 T251 | 16 | – | 1+ | UPVC, ABS, PP, Polythene |

| TP07 0123 | 19.23 | 16.4 | – | UPVC – 2 internal lugs each 0.75mm |

| TP02 T252 | 35 | – | 1+ | UPVC, ABS, PP, Polythene |

| TP02 T253 | 36 | – | 1+ | UPVC, ABS, PP, Polythene |

| TP05 T259 | 62 | 50.8 | – | UPVC |

Click on a thumbnail image for a larger version:

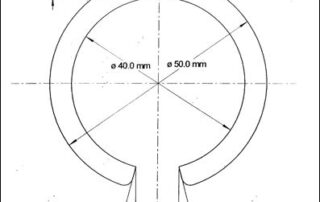

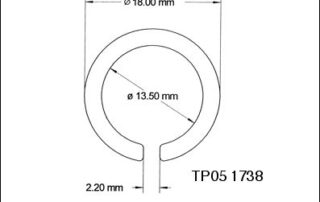

Split Plastic Tubes

There are two types of split tube, which are made using different methods.

a) Unless specified, the split tubes listed in the table below are made from dedicated tooling and resemble a tube with a small piece missing. Unlike hollow tubes, these are not made using a vacuum collett and cannot be made to variable wall thicknesses. They can be used as clip-on covers and sheaths.

b) It is also possible to make split tubing by extruding a hollow tube onto a blade which creates the split. For practical reasons this requires that the wall of the tube is thin (max 1mm), but means that many of the round tube sizes can be split during extrusion. For more information on this method please contact us and for tube sizes see our Round Tubes pages.

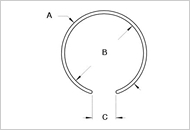

| Dimensions in mm | ||||

| Ref | A | B | C | Materials/Comments |

| TP02 T263 | 5 | 1.8 | 1 | UPVC, ABS, PP, Polythene |

| TP08 W131 | 8 | 6 | 3.1 | UPVC, bumps on outside at opening |

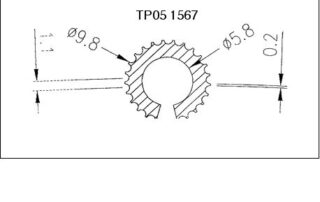

| TP05 1567 | 9.8 | 5.8 | – | UPVC, ABS, HIPS |

| TP08 W186 | 10 | 8 | 3.3 | UPVC, 90 degree legs at opening |

| TP02 T265 | 10 | 8 | 4 | UPVC, ABS, PP, Polythene |

| TP08 W039 | 13.3 | 10.7 | 1.3 | UPVC |

| TP02 T266 | 17 | 13.5 | 10 | UPVC, ABS |

| TP02 T268 | 18/7 | 16/5 | 5 | UPVC – Oval (see dwg) |

| TP05 1738 | 18 | 13.5 | 2.2 | UPVC, ABS, HIPS |

| TP08 W062 | 18.5 | 15.5 | 1 | UPVC |

| TP02 T267 | 18.5 | 15.9 | 10 | UPVC, ABS |

| TP08 W066 | 19 | 16 | 3 | UPVC |

| TP08 W065 | 19 | 16 | 8 | UPVC |

| TP08 W200 | 19 | – | 1.5 | UPVC |

| TP07 T261 | 19 | 18.4 | 0.5 | UPVC – split during extrusion (curls over) |

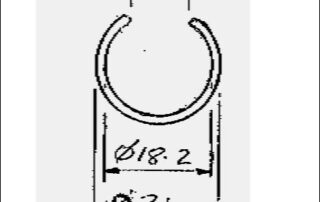

| TP02 T264 | 21 | 18.2 | 10 | UPVC, ABS, PP, Polythene |

| TP08 W202 | 19 | 16 | 3 | UPVC |

| TP07 T262 | 25 | 21 | 1 | UPVC, ABS, HDPE, PP, PC, Styrene |

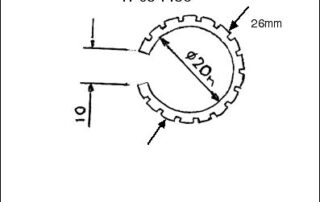

| TP05 1436 | 26 | 20 | 10 | UPVC, ABS, HIPS |

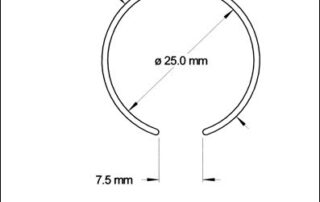

| TP05 1968 | 27 | 25 | 7.5 | UPVC, ABS, HIPS |

| TP05 2107 | 40 | 38 | 20 | UPVC |

| TP05 1945 | 50 | 40 | 10 | UPVC, ABS, HIPS |

| TP05 2067 | 59 | 57 | 37 | UPVC, ABS, HIPS |

Click on a thumbnail image for a larger version: