Variant Extruded Plastic Channels

The plastic extrusion tooling listed is for any profile which is predominantly a Channel, but there are additional features, e.g. nibs, flanges or barbs. Every effort has been made to describe the main features accurately, but please check the drawings at the bottom of the page or contact us to discuss bespoke Channel requirements so we can provide a drawing.

Custom tooling option available.

Alternatively, if a straightforward extruded plastic Channel profile would be suitable then click here for our comprehensive list of conventional Channels.

Stock Extruded Plastic Variant Channels

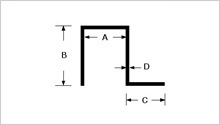

Tank Top is a plastic extrusion designed to fit over glass walls in aquaria and vivaria, with a flange to support a lid.

However if you cannot find what you are looking for we offer a Custom Plastic Extrusion Option and would welcome your enquiry.

Tank Top

| Dimensions in mm | ||||||

| Ref | Size | A | B | C | D | Materials / Comments |

| TP08 0115 | 6mm | 6.1 | 14.6 | 6.2 | 1.2 | STOCK black rigid pvc |

| TP08 0116 | 10mm | 10 | 15.9 | 10 | 1.2 | STOCK black rigid pvc |

Custom Extruded Plastic Variant Channels

Extruded Plastic Channels are listed in width order.

| Ref | Description | Base Shape | Comments (** dwg below) |

| TP08 W037 | 1 x 10 x 2.5 | Capping | One side spurs down 22.5mm total |

| TP05 1561 | 1.25mm gap Menu Holder | 17mm base, 12mm legs ** | |

| TP08 W172 | 2.4 x 19 x 1.2 | J Section | Small flange at base of long side |

| TP08 W174 | 2.6 x 5.5 x 19.5 x 1.4 | J Section | Tiny flange at base of long side |

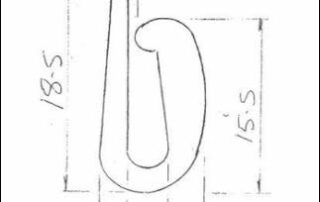

| TP02 C008 | 2.7mm Asymmetrical Clip | ** | |

| TP08 W080 | 3 x 8/30 x 1.2 | J Section | Small flange at base |

| TP08 W217 | 3 x 14 x 1.4 | Channel | Tank Top – wide flange at top |

| TP08 W327 | 3.3 x 8.5 | Channel | Wide notched flange from base |

| TP08 W215 | 3.8 x 20 x 28 x 1.3 | J Section | 12.8mm flange from long side |

| TP08 W025 | 4.5 x 7.5 x 1 | Channel | Side barbs and lips at opening |

| TP08 W089 | 5 x 2.5 x 8.8 | C Section | Tapering channel with 3 prongs on base |

| TP05 1475 | 5 x 6/13.5 x 1.5 | J Section | 15mm flange from long side |

| TP05 1322 | 6 x 6 x 1 | C Section | Legs taper in, internal nibs at opening ** |

| TP08 W154 | 6.5 x 10 x 1 | Channel | 45mm Spur down from base |

| TP08 W017 | 7 x 7.5 x 1.5 | Channel | Side flange |

| TP08 W155 | 7 x 16.8 x 1.8 | Channel | Outer nibs in middle of legs |

| TP08 W030 | 7 x 14.5 x 1.4 | Channel | Tank Top – 7.5mm flange at top |

| TP05 1623 | 7.3 x 6.5/13.5 x 1.5 | J Section | 39.5mm flange from long side |

| TP08 W121 | 8 x 8 x 2 | Channel | Nibs at opening – gap 6.8mm |

| TP08 2143 | 8.5 x 16 x 2.5 | Channel | 8.5mm flange at base |

| TP08 W190 | 9 x 18.6 x 1.5 | Channel | Internal hooks at opening, double flange at base |

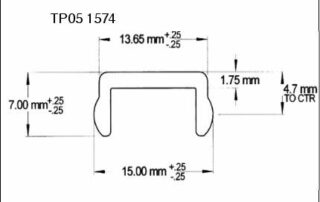

| TP05 1574 | 10 x 7 x 1.75 | Channel | Bulges on outside of legs ** |

| TP08 W180 | 11.6 x 18 x 1.2 | Channel | Nibs at opening – gap 8.1mm |

| TP08 W032 | 12.5 x 10.2mm | Channel | Internal nibs at opening |

| TP08 2110 | 12.5 x 9.5 x 1.2 | Channel | 13mm offset spine from base |

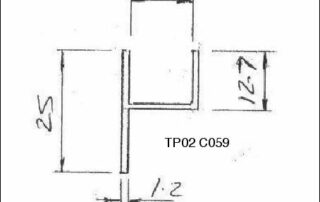

| TP02 C059 | 12.7 x 12.7 x 1.2 | Channel | One side continues down as flange ** |

| TP02 C029 | 13.5 x 8.8 x 0.8 | C Section | Internal nibs at opening ** |

| TP08 W203 | 16 x 21.5 x 2 | C Section | 12.8mm flange at base |

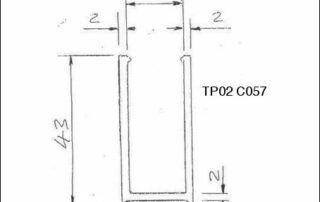

| TP02 C057 | 16 x 43 x 2 | C Section | Internal nibs at opening ** |

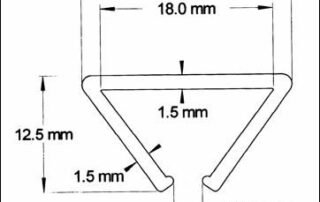

| TP05 1802 | 18 x 12.5 x 1.5 | Channel | Legs taper in, internal nibs at opening ** |

| TP08 W058 | 18.5 x 20 x 1.4 C | Section | Legs taper outwards to 25mm gap |

| TP08 W006 | 20.5 x 16 x 1 | Channel | Internal nibs near bottom of channel |

| TP02 C060 | 22.5 x 19 x 1.5 | Channel | Tank Top – 23mm flange at top ** |

| TP02 C061 | 22.5 x 19 x 1.5 | Channel | 24mm flange both sides ** |

| TP08 W125 | 25 x 24.5 | C Section | Internal runner within channel |

| TP05 1451 | 26 x 18.75 x 2.5 | Channel | 13.5mm flange both sides |

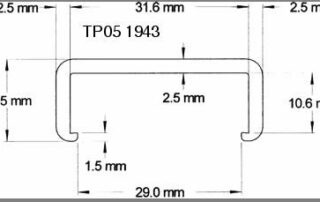

| TP05 1943 | 31.6 x 14.5 x 2.5 | Channel | Short lips at opening, radiused corners ** |

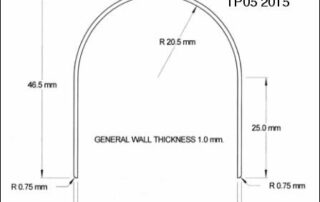

| TP05 2015 | 41 x 46.5 x 1 | Channel | Domed channel ** |

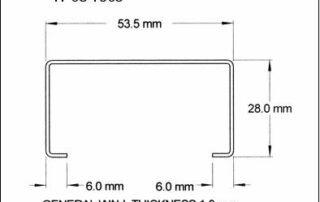

| TP05 1903 | 51.5 x 28 x 1 | Channel | 6mm lips at opening, radiused corners ** |

| TP05 1797 | 102 x 22 x 1 | Channel | 7mm lips at opening ** |